A gate valve is a valve whose closing member (gate) travels vertically along the centre line of the channel and is typically made up of the following parts: the valve body, the bonnet, the stem gate, the sealing packing, the handwheel/gearbox, and other parts. Typically, studs and nuts are used to secure the valve’s two ends to the pipeline’s flange.

An opening and closing mechanism for a gate valve is a gate. It moves in a direction that is vertical to the direction of the fluid flow. The gate valve cannot be modified or throttled; it can only be used as a shut-off valve. Gate valve sealing comes in two varieties: forced sealing and self-sealing. For self-sealing, the sealing can only be created by applying medium pressure, which presses the sealing surface of the gate against the valve seat on the opposing side to create the sealing. Forced sealing describes a situation where the sealing must be established by using an external force to move the gate plate toward the valve seat when the gate valve is closed.

The flow is unhindered when the valve is opened and the height of the gate is equal to 1:1 of the valve diameter. However, this location cannot be observed when in operation. In a real application, the position is fully expanded until the handwheel cannot be spun, at which point the valve stem’s maximum opening is utilized as a reference. It is advisable to open to the maximum position and turns back 1/2 to 1 turn as a reference to the completely open position of the valve because the handwheel may become stuck during temperature variations. As a result, the valve’s completely open position is determined by the gate’s position (i.e., stroke). Axegic Valve is a superior player for Manufacturing, supplying, and exporting Gate Valve from India.

Types of Gate Valves

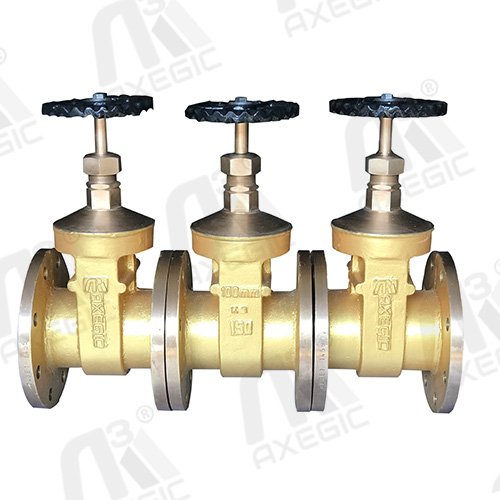

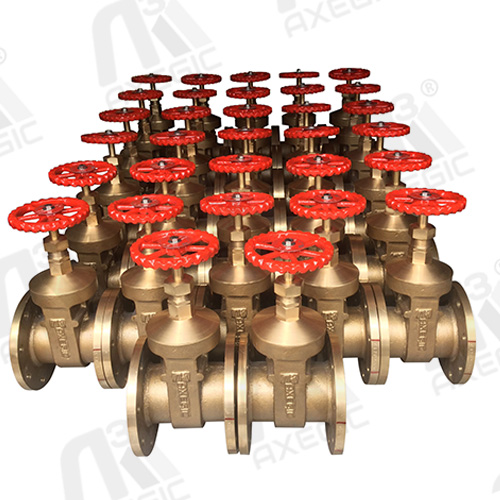

Among our popular products in India is the Gate Valve. Axegic Valve is engaged in providing unique products including Gate Valve and much more to various industries located in India. Manufacturer of a wide range of products which include Y Type Jacketed Gate Valve, Flanged End Gate Valve, Screwed Gate Valve, Butt Weld End Gate Valve, and Non Rising Stem Gate Valve.

| Sizes of Gate Valve | DN6 to DN50 ( NPS ¼ to NPS 2) |

| Pressure Rating | Class 150 & PN10 / PN 16 |

| Material Construction |

|

| Design & Manufacturing Standard | API 600, API 603 |

| Face to Face Std. | ASME B16.10 |

| End Connection Std. | ASME B16.5 |

| Testing Standard | API 598 |

| Type of Bore | Standard (Full Bore) |

| End Connection Type | Flanged Ends, Screwed Ends, Socket Weld Ends, Butt Weld Ends, Victaulic Ends, etc. |

| Valve Design | Rising Stem, Non-Rising Stem Flexible Wedge, Solid Wedge |

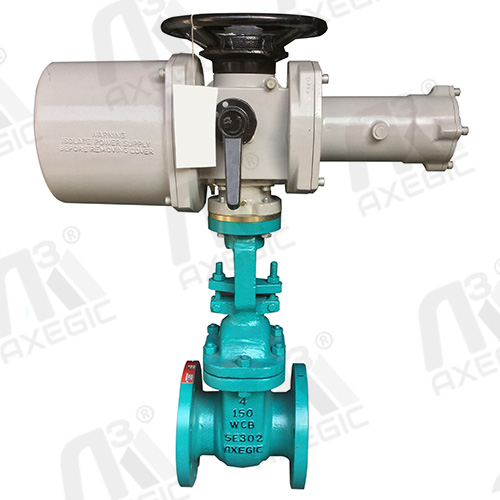

| Operated Type | Hand Wheel, Gear Box, Electric Actuator, Bare Shaft, etc. |